Electrical connectors are components that allow electrical circuits to be joined, separated, or reorganized without the need to modify the wiring permanently. They exist to ensure that electrical and electronic systems can be assembled, maintained, and upgraded easily and safely. Connectors are used in everything from household electronics and automotive wiring to aerospace systems and industrial automation.

As electrical systems grew more complex during the late 20th century, connectors became essential for ensuring wiring accuracy, maintaining signal integrity, and promoting electrical safety. Today, they are a foundational part of modern power distribution systems, electronic devices, communication networks, and renewable energy installations.

Electrical connectors help standardize how circuits interact. This standardization allows manufacturers and engineers to create compatible components across different industries. Whether used in automation equipment, consumer electronics, or medical devices, connectors help systems stay organized, efficient, and reliable.

Importance: Why Electrical Connectors Matter Today

Electrical connectors play a major role in technology, safety, energy use, and communication systems. Their importance has increased due to the growth of smart devices, electric vehicles, and advanced industrial equipment.

Electrical connectors matter for several reasons:

They improve system safety

Connectors reduce the need for manual wire joining, lowering the risk of electrical shorts, loose connections, or overheating. High-quality connectors also support electrical safety compliance by securing wiring in environments where vibration, moisture, or high temperatures are concerns.

They support maintenance and upgrades

In sectors such as manufacturing, aviation, and telecommunications, connectors allow technicians to replace components without disrupting entire systems. This reduces downtime and makes equipment management more predictable.

They support the rise of renewable energy

Solar panels, wind turbines, and energy-storage systems rely heavily on connectors to manage power distribution. Connectors help ensure stable current flow, which supports the growth of sustainable power systems.

They help engineers manage complex designs

Modern electronics use specialized connectors to:

-

reduce wiring clutter

-

maintain signal integrity

-

support high-speed data transfer

-

protect against electromagnetic interference

In industries like automotive engineering, medical equipment development, and robotics, connectors ensure that systems remain precise and dependable.

Who benefits from electrical connectors?

-

Engineers and designers

-

Technicians in manufacturing or maintenance

-

Students studying electrical engineering fundamentals

-

Organizations working with automation, renewable energy, or communication networks

-

Everyday users of consumer electronics

Electrical connectors solve the essential problem of linking circuits safely and efficiently while enabling flexibility and innovation across countless technologies.

Recent Updates: Trends and Developments in Electrical Connectors

The electrical connector industry continues to evolve with advancements in automation, electronics, and mobility. Several developments over the past year highlight this progress.

Growing demand for high-voltage EV connectors (2024–2025)

The expansion of electric vehicles has increased interest in high-voltage connectors designed to handle fast charging and battery-management systems. Manufacturers introduced new insulated connectors in mid-2024 to improve thermal stability and reduce electrical resistance.

Miniaturization of connectors for wearables and IoT (2024)

Small form-factor connectors became more common in early 2024, supporting compact devices such as medical monitors, smart sensors, and portable electronics.

Rise of waterproof and corrosion-resistant connectors

Industries such as marine engineering and outdoor automation showed greater demand in 2024 for connectors with improved sealing features. New IP67 and IP68-rated connectors were released to support harsh-environment applications.

Improved standards for industrial wiring systems

As of late 2024, updated global standards emphasized better performance in high-vibration environments and more robust shielding for signal connectors. This supports the continued growth of automation and advanced manufacturing.

Sustainable materials and reduced environmental impact

Manufacturers began shifting toward recyclable plastics and metal alloys in 2024 to align with environmental guidelines and lower carbon footprints across supply chains.

Laws or Policies: How Regulations Affect Connector Use

Electrical connectors fall under various safety, engineering, and product-compliance rules. These regulations support safe installation, proper use, and standardization across industries.

Some of the key laws and standards include:

National Electrical Code (NEC) – United States

The NEC outlines requirements for safe electrical installations and specifies connector ratings, grounding methods, and current-carrying capacity. It ensures connectors meet criteria for insulation, fire resistance, and electrical continuity.

IEC Standards – International

The International Electrotechnical Commission provides global standards for electrical and electronic equipment, including:

-

connector dimensions

-

current and voltage ratings

-

environmental protection ratings (IP codes)

-

material and performance testing

IEC 60352 and IEC 61984 are widely recognized standards for connector safety.

RoHS (Restriction of Hazardous Substances)

RoHS regulations limit the use of hazardous materials such as lead and mercury in electrical components. This affects connector manufacturing materials and promotes environmentally responsible design.

UL Certification

Underwriters Laboratories provides testing and certification for electrical components used in North America. UL-approved connectors are evaluated for durability, thermal stability, and safe performance under specified electrical loads.

Automotive and aerospace requirements

Specialized industries follow additional regulations such as:

-

ISO/TS 16949 for automotive components

-

AS9100 for aerospace quality management

These policies ensure connectors used in critical applications meet stringent safety criteria.

Tools and Resources: Helpful Support for Understanding Electrical Connectors

Several tools, databases, and educational platforms help engineers, students, and technicians understand connectors more clearly.

Technical Reference Platforms

-

IEC Standards Database for international guidelines

-

UL Product IQ for certifications and compliance

-

IEEE Xplore for research on electrical engineering components

Design and Configuration Tools

-

Online wiring calculators for connector current ratings

-

CAD libraries offering connector models for design projects

-

Electrical schematics software such as KiCad or Fritzing

Learning Resources

-

Online engineering tutorials

-

Interactive diagrams showing connector types and pin configurations

-

Manufacturer datasheets explaining voltage ratings and environmental performance

Example Table: Common Connector Types and Key Features

| Connector Type | Main Use | Notable Feature |

|---|---|---|

| USB Connector | Data and power | Universal compatibility |

| Terminal Block | Industrial wiring | Secure screw-type connection |

| Coaxial Connector | RF communication | Shielding for signal integrity |

| Circular Connector | Outdoor/industrial | High durability and sealing |

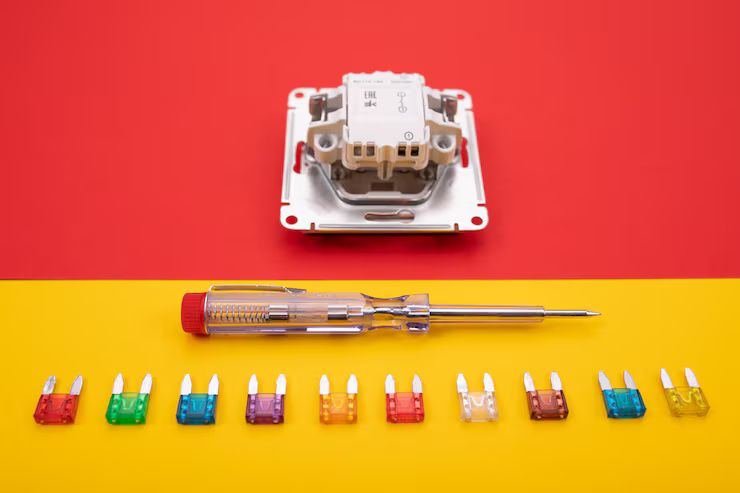

| Blade/Fuse Connector | Automotive wiring | Quick replacement and protection |

FAQs

What is the main purpose of an electrical connector?

An electrical connector allows two or more electrical circuits to join or disconnect safely without altering the wiring permanently. It improves system flexibility, maintenance, and safety.

How do I know what connector type to use?

Connector selection depends on voltage rating, current rating, environmental conditions, signal requirements, and compatibility with equipment. Industry standards and datasheets help guide proper selection.

What does an IP rating mean for connectors?

An IP (Ingress Protection) rating indicates how well a connector protects against dust and moisture. Higher numbers, such as IP67 or IP68, provide stronger protection in harsh or outdoor environments.

Are all connectors interchangeable?

No. Connectors differ in size, shape, pin configuration, electrical rating, and compatibility. Using incompatible connectors can lead to poor performance or safety issues.

Why do some connectors include shielding?

Shielded connectors reduce electromagnetic interference, which is essential for high-speed data transfer, communication systems, and medical equipment.

Conclusion

Electrical connectors play a vital role in powering modern technology, supporting safe wiring practices, and enabling complex electronic systems to function reliably. Their importance continues to grow as industries adopt automation, renewable energy, electric vehicles, and advanced communication technologies. With ongoing improvements in safety standards, materials, and design, connectors support innovation while ensuring compliance with national and international regulations.

Understanding the basics of connector types, industry standards, and recent trends helps engineers, students, and everyday users make informed decisions about electrical and electronic systems. As technology progresses, connectors will remain essential for ensuring safe, stable, and efficient electrical connections across all applications.